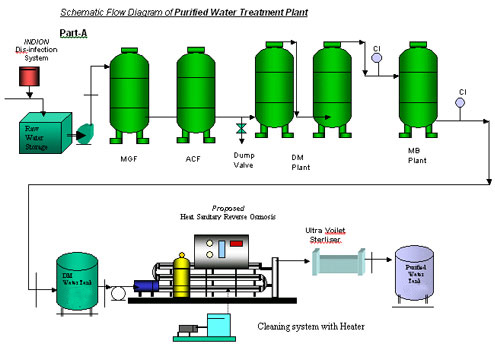

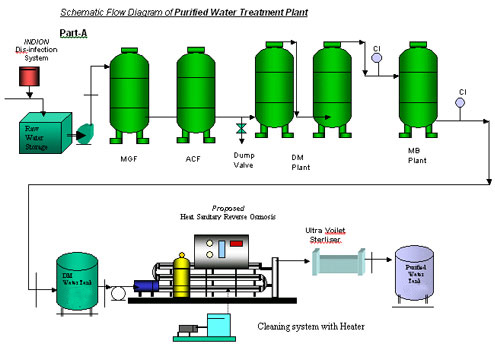

Raw water supply: Raw water is pumped out from the underground bore well to overhead tank

MULTIGRADE SAND FILTER :

Potable water is passed through the Multigrade Sand Filter under pressure, generated by gravitational force of the overhead water tank. The coarse particles from the potable water are filtered. Back washing of the sand filter bed is done for cleaning of the filters & reducing the pressure drop while the plant is in operation. Pressure for back washing required is about 1.5 kg/ sq. cm, which is provided by gravitational force of overhead water tank.

ACTIVATED CARBON FILTER:

The potable water filtered through Multigrade Sand Filter is then passed through Activated Carbon filter. Free Chlorine, Colour & Odour if present in the water is removed. Back washing of the filter bed is done for cleaning the filters & reducing the pressure drop while the plant is in operation. Pressure for back washing required is about 1.5 kg / sq.cm, which is provided by gravitational force of overhead water tank.

EXCHANGER UNIT: (SAC, SBA, MB UNIT)

All exchanger units are painted externally with oil paints and are of MS. Internal Surface of columns are rubber lined to avoid iron pick up produced by corrosion. Provision for counter current regeneration is available for this unit.

Strainers of PVC construction are installed in backwash out-let of exchanger to prevent resin loss during backwash operation.

Columns are provided with dished ends. Proper breather seals are also provided with all units. All the Cations & Anions present in the water are exchanged in the Exchanger Unit. Purified water output is connected with SS pipeline to the point of use with COLD LOOP SYSTEM.

UV DISINFECTION SYSTEM:

Out put of Purified Water plant is subjected for disinfections by Ultra Violet radiation of UV lamp.

| Max flow capacity |

: |

3200 LPH |

| Inlet/Outlet diameter |

: |

1" |

| UV Lamp (Volts: 230) |

: |

1- U.V lamp (Phillips, Holland) |

Lamps are changed after total 7500 hours of burning.

System gives Purified Water of high purity required for use in washing of primary packing materials (glass bottles), for rinsing of equipment's & for manufacturing of formulations.

The average treated water-quality, qualify the IP 1996/BP monogram.

OPERATION:

- Plant operates by Raw Water Pump connected with the storage tank.

- Potable water is passed through multigrade sand f1lter, activated carbon

- Cation exchanger unit having strong acidic Cation (SAC) exchanger resins is

- followed by Anion exchanger unit having strong basic anion (SBA) exchange

- resins, followed by mixed bed exchanger unit that is mixture of SAC & SBA.

- Mixed bed unit acts as a polishing unit. System gives Purified water of high purity required for use in washing of primary packing materials (glass bottles), for rinsing of equipments

- The treated water quality, qualify the IP monograph in addition to the below

| Residue on evaporation |

= |

NMT 0.001 % |

| Conductivity |

= |

< 1 micro Siemen / cm |

| Microbial (CFU / ml) |

= |

NMT 100 |

mentioned specifications:

Residue on evaporation = NMT 0.001 %

Conductivity = < 1 micro Siemen / cm

Microbial (CFU / ml) = NMT 100

Ø - The Purified Water produced is stored in the SS316 Storage Tanks of Capacity of 3,000 Liters.

Ø - Purified Water produced is distributed through the SS 316 pipelines to various out lets with a loop system. In the Mfg and also in the Bottle Washing Area, Purified Water is passed through UV Disinfections System before use.

Ø - Quality of Purified Water is tested for IP (1996)/ BP specifications.

Water system is validated for Phase I ,phase II ,phase Three Ongoing.

|